Ojai Olive Oil

I recently spent an afternoon with Alice Asquith, who showed me around the Ojai Olive Oil company’s olive grove and pressing operation, and learned so much more about the amazing olive. It was a gorgeous summer day in Ojai, and Alice was kind and gracious.

A Little History…

In 1982, Alice’s husband, Ronald, bought a ten acre orange grove as a retirement project. They moved to Ojai from metropolitan Los Angeles, and eventually replanted the grove in olives. In 1998 he bought 36 more acres, where they now have the center of their operation. This grove had been planted in 1880! The original farmers made oil until 1910, but after that the trees just sat — for 78 years. No oil was made from the olives–they just fell to the ground and rotted. Ron began to give them lot of TLC, and after just three years, the trees began to produce beautifully. In 2001 they made their first olive oil. The entire grove is now certified organic.

Three years ago they started suppling their oil to a cosmetic maker, and they have lovely soaps and creams made from their oil.

Ronald spent many hours studying and learning about olive growing, and he had some wonderful mentors to help him along his way. The groves now have over 3000 trees, which are thriving, but Alice said that “the weather is the boss.” From budding to harvest, the trees must be nurtured.

|

| Photo from Ojai Olive Oil |

The olive trees blossom in late April or so, and it takes six months from blossom to first harvest. The olives will stay green for as long as possible, and then they start to ripen in early October. During the harvest time they have to constantly watch the olives to make sure they harvest at the right time. They wait until most of the olives are ripe–have turned color–then they harvest, all by hand.

|

| Photo from Ojai Olive Oil |

It takes sixty pounds of olives to make one gallon of olive oil! But if the weather has been very hot, the yield will be a little higher. The olives are taken directly from the groves to be milled the day they are harvested.

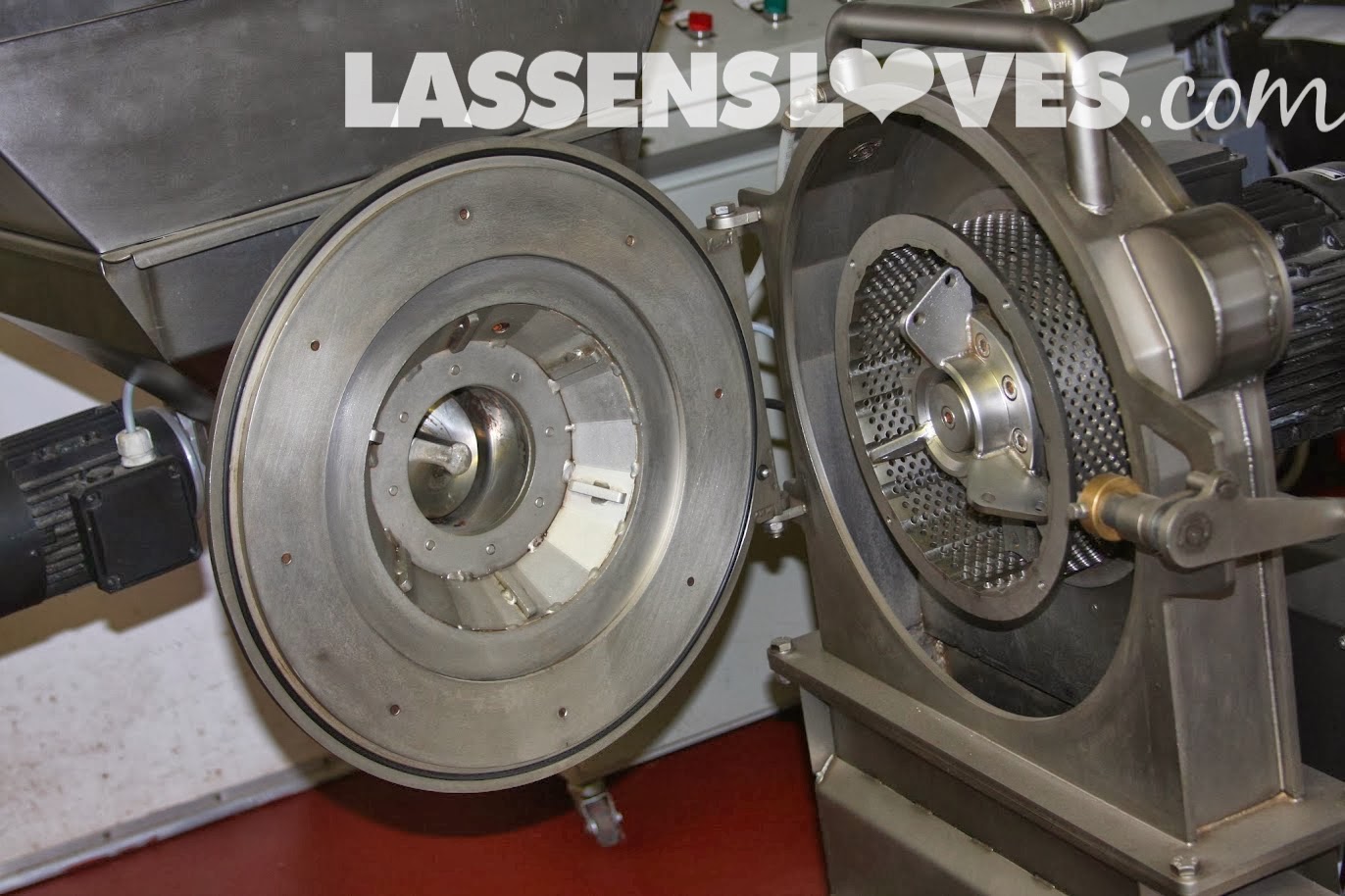

First the olives are washed and the leaves blown off, and then the olives are crushed–chopped and pushed through a sieve.

You can see how the olives would be crushed as they moved down through this part of the machine and into the next step!

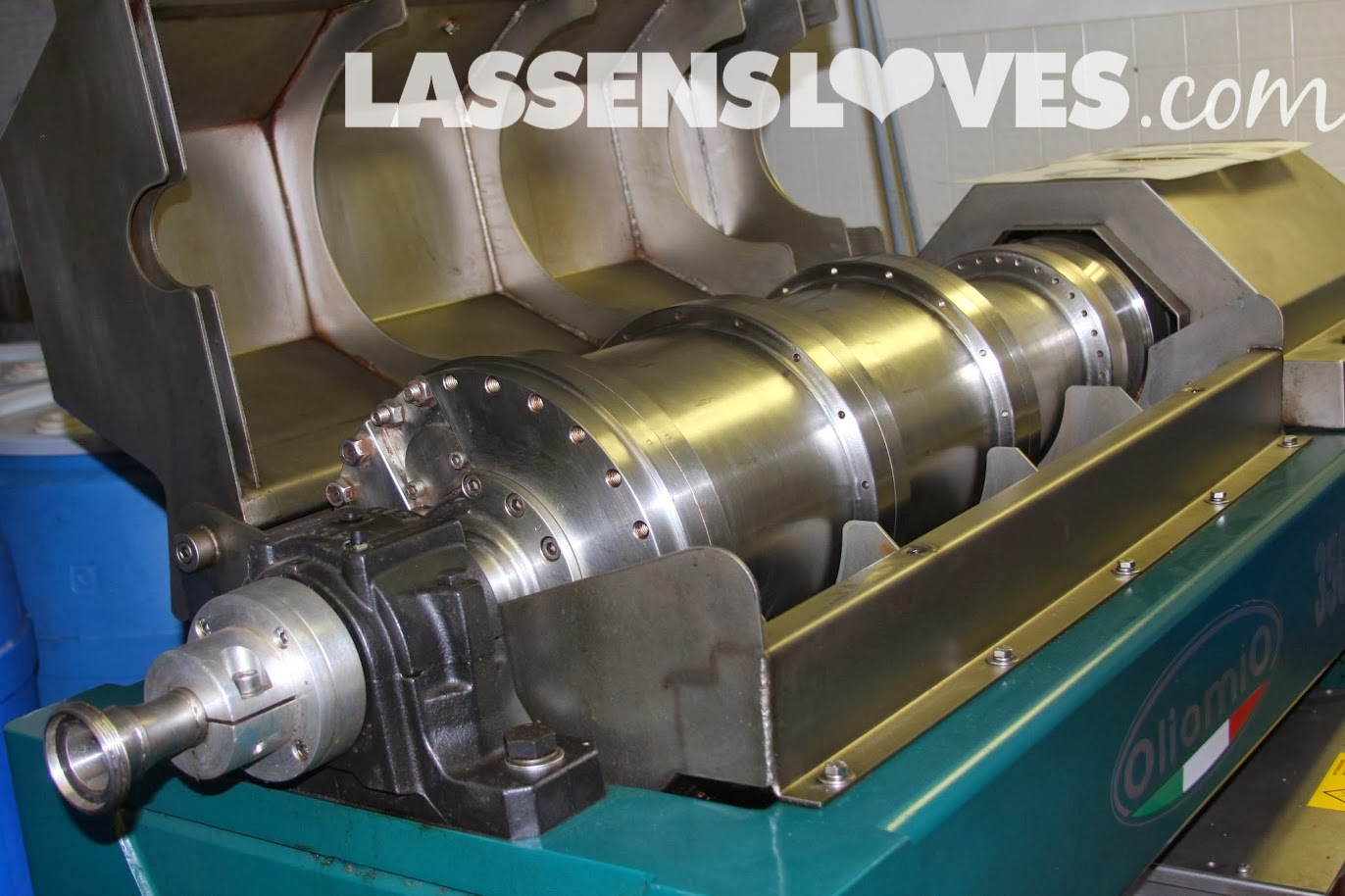

Once it moves into the drums, the olives are now the consistency of paste, and looks sort of like oatmeal.

|

| Photo from Ojai Olive Oil |

The paste is stirred up slowly. No heat or water is added. It is protected from air to prevent oxidation.

The paste begins to separate, and then the centrifuge begins to spin to assist the separation by density and weight. It takes 90 minutes from start to finish! They can process up to 800 pounds of olives per hour. The oil is strained and bottled.

|

| Photo from Ojai Olive Oil |

The International Olive Oil Council (IOOC) has established standards for extra-virgin olive oil. A sample of every batch of Ojai Olive Oil is sent to a lab for blind testing to make sure it meats the highest standards, and has less than 0.8% acidity.

|

| Photo from Ojai Olive Oil |

At the end of the process, there is a waste made of pulp, skins, and pits, shown above. Ojai Olive Oil Company uses this to make compost.

Ojai Olive Oil Company also gives free tours and tastings at their grove. You can see the machines and taste the oils! For times and more detailed information about their ranch and story, click here.